INDEX-Traub Group INDEX MS40-8 | CNC Multi-Spindle Automatic LatheAvailable

Save

Share

INDEX-Traub Group

To be updated

Condition: New

Scale: Production

Status: Ready-to-Ship

Ships From: USA

Product Description

Summary

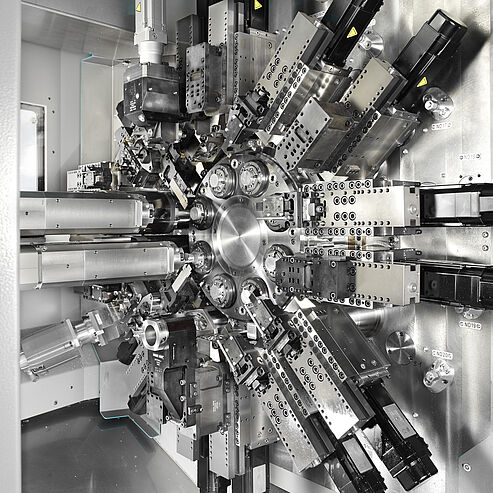

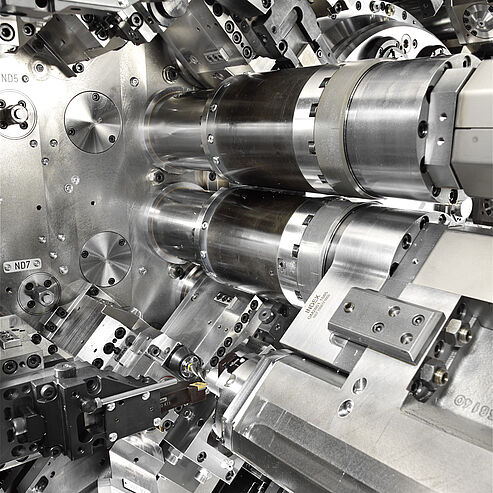

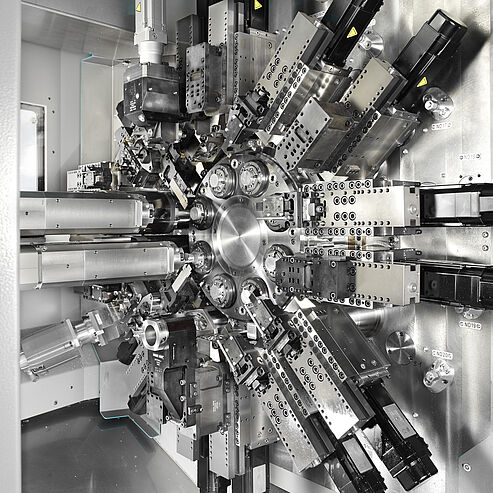

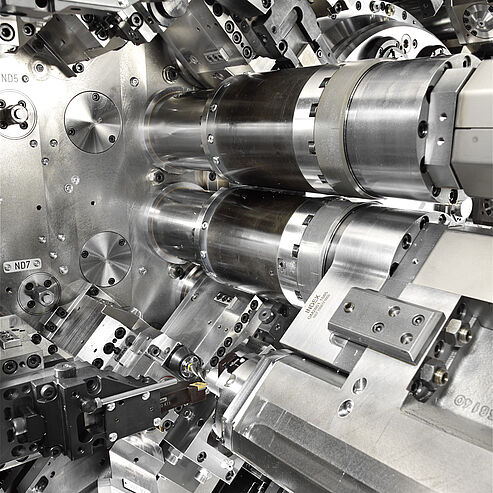

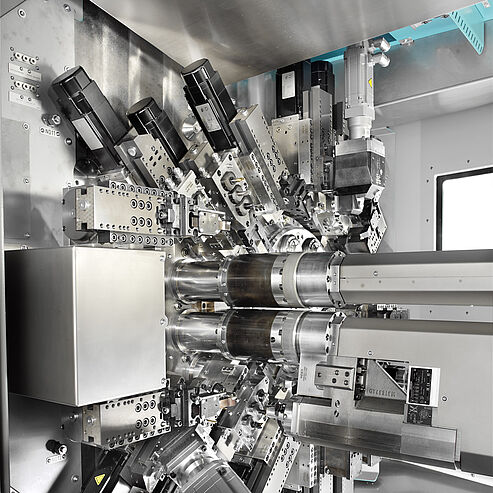

The INDEX MS40-8 is a CNC multi-spindle automatic lathe engineered for simultaneous, high-speed machining of complex bar and chuck parts. It features eight fluid-cooled, motorized spindles with fast, programmable speed control and integrated C- and Y-axes for advanced operations such as off-center drilling, milling, and hobbing. Its distinctive slide kinematics and the use of a Hirth coupling for drum indexing support both cycle time reduction and high positional accuracy during multi-tool, multi-axis production.

Key Capabilities

- Simultaneous machining with up to eight independently driven spindles

- Complex machining operations including off-center drilling, milling, hobbing, and polygon turning

- Bar and chuck part machining with robot-assisted loading/unloading and directed part discharge

- Programmable spindle speed for each station, with speed changes possible during indexing

- Capable of machining high-strength materials that are challenging for typical multi-spindle platforms

- Support for 1, 2, or 3-axis tool carriers and driven tool positions for backworking

- Fast indexing with three-piece Hirth coupling for high-precision work

Key Specifications

| Parameter | Value | Unit |

|---|---|---|

| Number of working spindles (max) | 8 | |

| Bar capacity (max) | 40 | mm |

| Spindle speed (max) | 7,000 | rpm |

| Main spindle power (25%) | 24 | kW |

| Main spindle torque (25%) | 57 | Nm |

| Tool carrier (max number) | 16 | |

| Machine weight | 10,300 | kg |

| Connecting power | 66 - 104 | kW |

| Control system | Siemens S840D sl |