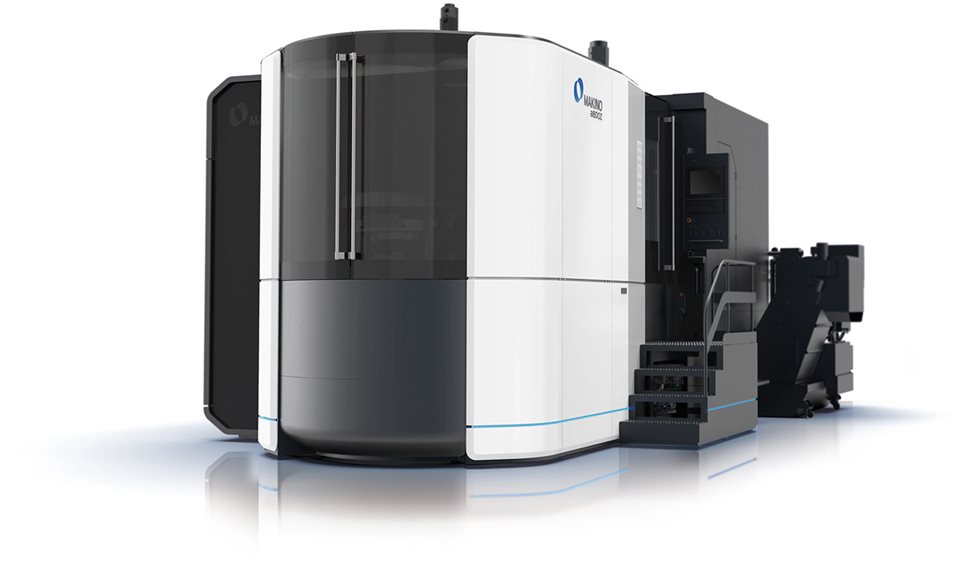

Makino a800Z | 5-Axis Horizontal Machining CenterAvailable

Save

Share

Makino

To be updated

Condition: New

Scale: Production

Status: Ready-to-Ship

Ships From: USA

Product Description

Summary

The Makino a800Z is a 5-axis horizontal machining center designed for complex part production with integrated Z-type rotary axes. It enables multi-face machining in a single setup, supporting large and heavy workpieces with a high-power spindle and pallet changer system. Distinctive features include direct drive rotary axes and closed loop active temperature control for dimensional stability.

Key Capabilities

- 5-axis machining with integrated Z-type rotary table for advanced part geometries

- Simultaneous multi-face machining and reduced workpiece setups via automatic pallet changer

- Accommodates workpieces up to Ø1000 mm x 800 mm high, 1000 kg payload

- Direct drive rotary tables: unlimited 360° (B-axis), 180° (C-axis)

- Closed loop active temperature control for all axes

- High-power spindle: standard 10,000 RPM (73.8 HP, 532 ft-lbs torque); optional 8,000 RPM high-torque spindle

- Pro-6 CNC control with user interface and advanced tool data management

- Rapid traverse of 60,000 mm/min on linear axes

- Standard 60-tool automatic tool changer, with tool-to-tool change of 1.8–1.9 seconds

Key Specifications

| Parameter | Value | Unit |

|---|---|---|

| Maximum Workpiece Size | Ø1000 x 800 | mm |

| Maximum Payload | 1000 | kg |

| X Stroke | 1280 | mm |

| Y Stroke | 1200 | mm |

| Z Stroke | 1120–1325 | mm |

| B-Axis Range | 360 (unlimited, direct drive) | ° |

| C-Axis Range | 180 (direct drive) | ° |

| Spindle Speed (Std./Opt.) | 10,000 / 8,000 | RPM |

| Pallet Size | 630 | mm |

| Tool Capacity (ATC) | 60 | tools |

| Maximum Tool Diameter | 356 | mm |

| Maximum Tool Weight | 30 | kg |

| Tool-to-Tool Change | 1.8–1.9 | sec |

| Rapid Traverse | 60,000 | mm/min |

| Cutting Feedrate | 50,000 | mm/min |