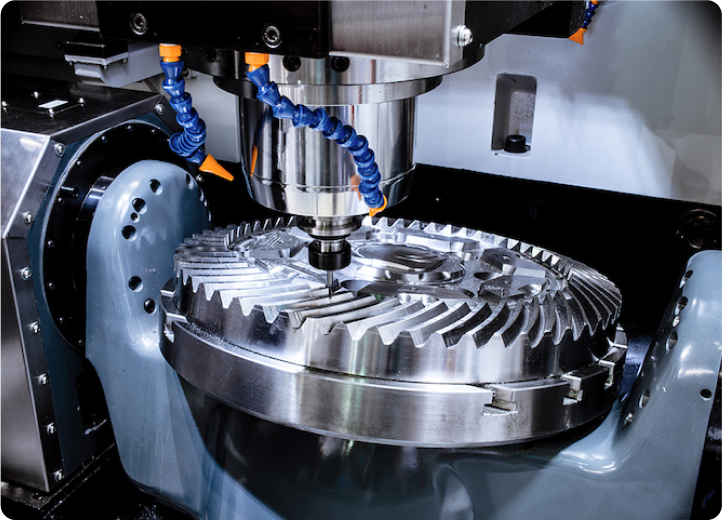

Calendering

Calendering machines play a vital role in compressing copper or aluminum foil coated on both sides using a rotating pair of rollers. Before compression, the electrode foil undergoes static discharge and is cleaned with brushes or air flow. The material is then compacted between the top and bottom rollers, which apply a precisely defined line pressure. This pressure influences the porosity of the coated material, affecting electrode wetting properties and cell energy density. After calendering, the electrode foil is cleaned again and rewound in a roll-to-roll process. Proper roller cleanliness is essential to prevent foreign particles from contaminating the substrate. Excessive line pressure can cause stress cracks due to material squeezing, making precise control crucial for maintaining quality and performance.

Calendering Machine

Spacer

Spacer

Build New

Our Marketplace Keeps Getting Better

Premium Factory Equipment

Discover high-value specialized equipment from premium suppliers

Exclusive Listings

Gain access to exclusive listings on inventoried and surplus equipment from certified sellers

Discounted Pricing

Take advantage of special pre-negotiated pricing

Sign Up for Free

New Listing Notifications

Be the first to know about new product listings, before everyone else

Early Access to Sales

Members are instantly notified when their saved equipment goes on sale

Save for Later

Ability to save and monitor listings for price drops, availability, and more