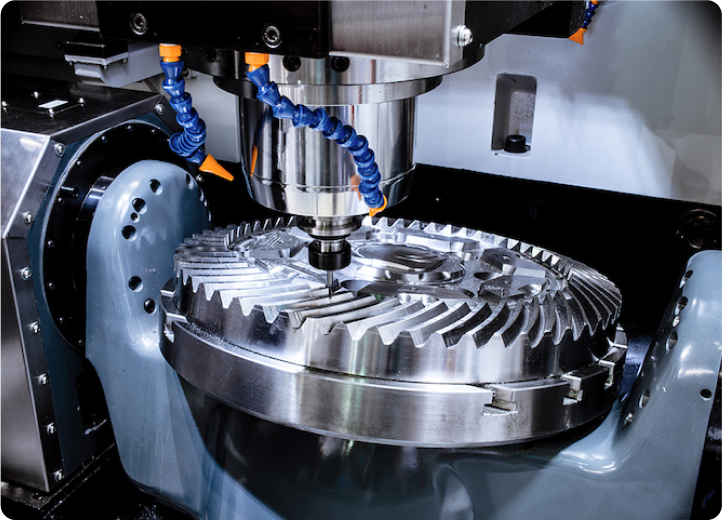

Coating Equipment

A coating line ensures high-quality electrode coatings for energy storage applications. The process involves coating foil with a specially formulated slurry using application tools like slot dies, doctor blades, or anilox rollers. Coating can be continuous or intermittent, typically applied sequentially on both sides. After the initial drying phase, the foil is manually fed back into the system for second-side coating. Industry-standard materials such as rolled aluminum foil for cathodes and rolled or electrolytically produced copper foil for anodes are used, with thicknesses ranging from 5 μm to 25 μm depending on cell design. Precision techniques and strict quality control ensure excellent adhesion, conductivity, and durability, meeting the highest industry standards.

Coating Line

Spacer

Build New

Our Marketplace Keeps Getting Better

Premium Factory Equipment

Discover high-value specialized equipment from premium suppliers

Exclusive Listings

Gain access to exclusive listings on inventoried and surplus equipment from certified sellers

Discounted Pricing

Take advantage of special pre-negotiated pricing

Sign Up for Free

New Listing Notifications

Be the first to know about new product listings, before everyone else

Early Access to Sales

Members are instantly notified when their saved equipment goes on sale

Save for Later

Ability to save and monitor listings for price drops, availability, and more