Lyric Automation

Huicheng District, Huizhou 516057, China

About

Guangdong Lyric Robot Automation Co., Ltd. was established in November 2014 and is headquartered in Guangdong, China, manufacturing automated production equipment for battery, automotive, and electronics industries.

The company designs and builds complete production lines from raw material processing through final testing, specializing in battery cell manufacturing (lithium-ion, solid-state), automotive component assembly, server manufacturing, and material handling automation.

Company Details

- Year Founded: 2014

- Headquarters: Guangdong, China

- Manufacturing Locations:

- China: Facilities in Huizhou, Ningde, Shanghai, Wuhan, Nantong, Shenzhen

- Europe: UK, Poland, France, Switzerland, Germany, Hungary

- North America: Canada, USA

- Employee Count: 5,000+ (2,000+ technical & R&D team including academicians, doctors, masters)

- Global Presence:

- Technical Support: China, Europe, North America, Asia-Pacific

- Sales: 20+ global subsidiaries and offices

- Service Centers: Thailand, India, Vietnam, Japan, Korea, Indonesia

Battery Manufacturing

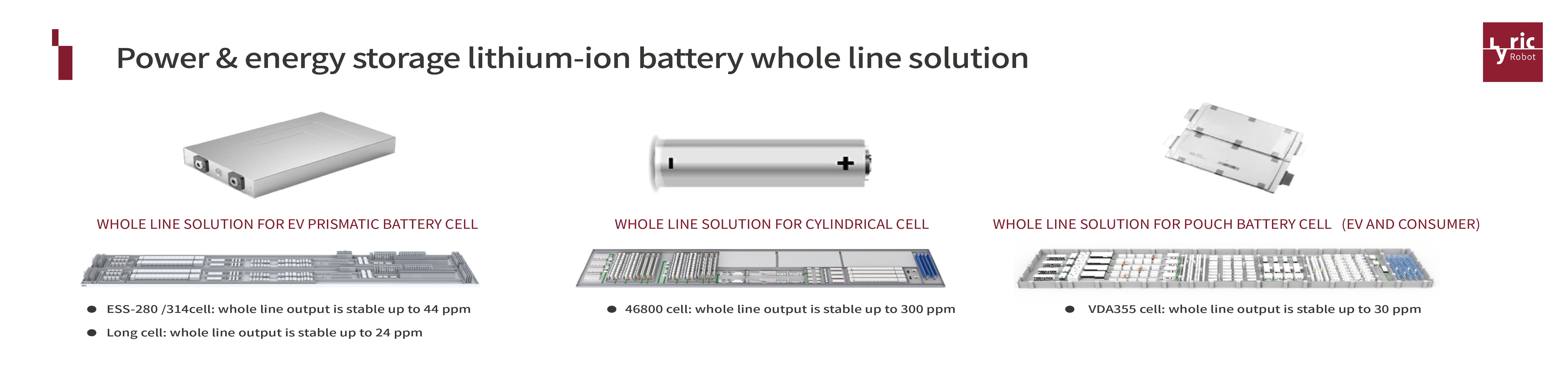

Complete Production Lines: Prismatic (6-300 PPM), Cylindrical (6-300 PPM), Pouch (6-300 PPM), Solid-state battery lines

- Electrode Manufacturing:

- Mixing and coating systems (up to 120m/min, 1800mm width)

- Calendering and slitting machines

- Electrode preparation systems

- Cell Assembly:

- Stacking/winding systems (≥99.5% yield rate)

- Tab welding and sealing systems

- Electrolyte filling systems

- Formation & Aging:

- Formation systems

- Aging equipment

- Final testing automation

- Quality Control Equipment:

- X-ray and visual inspection equipment (0.01μm precision)

- Leak testing systems

- Automated sorting and grading systems

Process Equipment

- Perovskite solar cell production lines

- Hydrogen fuel cell assembly lines

- Server manufacturing lines

- Automotive component assembly lines (electric drive, door locks, hinges, lighting)

- Humanoid robot component assembly and testing lines

Material Handling Equipment

- Automated warehouse systems

- Production material flow automation

- Factory logistics automation

AGV systems for material transport

Custom Engineering Capabilities

- Complete production line customization across all industries

- Turnkey factory automation from raw materials to finished goods

Manufacturing Advantages

- Scale Capabilities:

- 5,000+ employees with 2,000+ technical staff including academicians, doctors, masters

- Production capacity: 3,000+ equipment sets annually

- 20+ global facilities for local support and service

- Technical Integration:

- Seven integrated technology platforms: intelligent perception, control technology, execution technology, intelligent storage technology, laser application technology, digital technology, vacuum technology

- Turnkey capability from raw materials to finished product testing

- AI-based quality control with 0.01μm precision inspection

- In-house laser processing capabilities: welding, cleaning, marking, cutting, strengthening, cladding, additive manufacturing, TGV

- Manufacturing Track Record:

- Tier-1 customers: CATL, BYD, Samsung, Volkswagen, ATL, Gotion High-tech, Xinwang Da, Vision, GAC Group, Changan Automobile

- Complete production lines delivered across multiple industries

- Cross-industry expertise: battery, automotive, solar, hydrogen, electronics

- Systems Integration:

- Integrated software suite: ICAD, SRM, MES, QMS, EHM, WMS, IBMS

- Complete factory automation from material handling to quality control

- Single-source supplier reducing integration complexity

Industry Applications

- Primary Industries Served:

- Battery Manufacturing: Lithium-ion (EV, consumer electronics), solid-state batteries, energy storage systems, hydrogen fuel cells

- Solar Manufacturing: Perovskite solar cell production

- Electronics: Server assembly and testing

- Automotive: Electric drive systems, door locks, hinges, automotive lighting

- Robotics: Humanoid robot component manufacturing

Certifications & Compliance

- Quality Certifications: ISO 9001

- Environmental Standards: ISO 14001

- Safety Compliance: ISO 45001

- Information Security: ISO 27001

- Market Listings: STI Board (Listed 2021)

- Additional Certifications: CMMI3 certified, CE certification

- Intellectual Property Management: GBT29490

Regions Served

South KoreaJapanCanadaUnited StatesPolandHungaryGermanyChina

Product Offerings

Winding MachineTesting & SortingStacking MachineSolar Cell Scribing SystemSlitting MachinePrismatic Logistics LinePouch Logistics LineNotching MachineLaser WeldingElectrolyte Filling MachineCalendering MachineAssembly EquipmentAging Equipment

Published Listings

52 results

Preview Products

13 results